Welcome to The Dickerson Site- Updated 2/17/2026, please see News & Updates section

Notes On Rods and Models

As stated on his business card and stationary, Dickerson was a custom rod maker. This should be kept foremost in mind when contemplating his rod models. While he certainly had a taper philosophy, Dickerson's model designations were truly only rod length and ferrule size. Everything else that occurred in between was what made the action and that was never set in stone.

In reviewing the Dickerson production ledgers, the extent to which he did custom work begins to emerge. A portion of his order entries, especially after 1940, contain a caveat next to the entry. In the following example the model 8013 is used. The notations following the model are a real sampling of how Dickerson made the ledger entries.

- 8013 "stiff"

- 8013 D line

- 8013 hollow

- 8013 like Dr. Munson's (referring to a previous customers rod was common)

- 8013 special

- 8013 dry fly

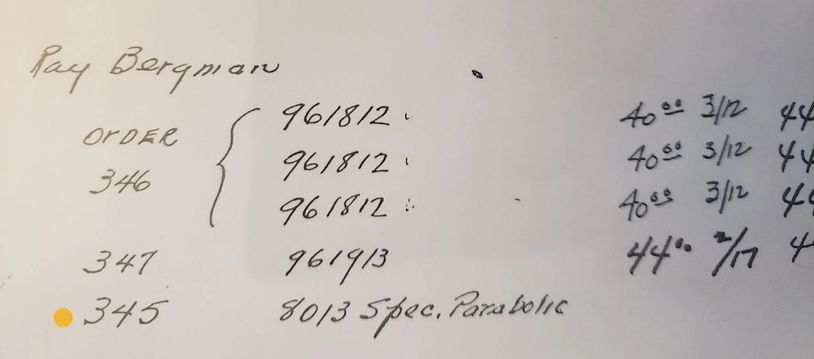

- 8013 Spec. Parabolic

- 8013 light action

A 1946 ledger entry showing a Ray Bergman order for an 8013 Special Parabolic

In general, the action of Dickerson's rods changed as his career progressed. There are always exceptions, but his post-war rods are faster in action than the pre-war rods. The rods evolved with the times and preferences of his customers. In addition to a quicker action, there was much more focus on two piece models after 1940.

Dickerson did not record in the production ledger how he might have altered a taper for a particular rod he made, other than the occasional short note after the model as shown in the previous table. In the late 1930s, Dickerson designed and built the milling machine that he would use until the end of his career. During this period, he also designed and made the taper templates used to produce his standard models. Dickerson could alter the tapers by shimming his templates, slipping a strip within the template, or by cutting less or more of a strip on the final pass. For example, most model 801510s vary slightly to moderately. One could be fast action taking a five or six weight line and another, a delicate four weight.

One of the results of changing a model's taper significantly is the problem of ferrule size. Dickerson would often mount a slightly undersized ferrule on a blank, meaning he would cut off more material at the ferrule station than what was normally done in order to install a ferrule that probably should have been one size larger. Dickerson did this with some frequency, especially on post 1940 rods. I am certain it was done consciously but it serves no practical purpose other than keeping a model designation in line with what was originally ordered. Some might raise concern about the structural integrity of this practice, but Dickerson knew well the limitations of material he was working with. I have never seen or heard of a Dickerson rod breaking at the ferrule due to this practice.

In addition to the ferrule installation choices outlined previously, there is another fairly common curious feature with Dickerson's post-war rods. Some have slightly different length sections and also inconsistent overall finished rod lengths. Indifference is the only reason that comes to mind when considering the possibilities of how this occurred. Perhaps it was a relaxed approach to rod making during an era when certain details were not as closely scrutinized; the results of which would not be acceptable today. Generally Dickerson rods prior to 1940 are the correct overall length and have equal length sections. His work after 1940 is not as consistent. Rods might have sections varying up to 3/16” inch, obviously not short enough to have ever been broken or altered. Some of his two piece rods might have tips that are 3/16th inch shorter than the butt, but the rod measures full length when assembled. Paradoxically, other two piece rods that have equal length sections and are 100% original, might measure 1” shorter than the stated rod length when assembled; such as an eight foot model measuring 7'11". Despite these intermittent occurrences, many Dickerson rods have the correct section and finished length regardless of era.

Personally, I would rather have a Dickerson that measures the stated length than shorter.

However, a slightly short rod does not bother me if it is all original. If you understand this fairly common occurrence and learn how to evaluate a Dickerson rod’s originality, buying such a rod is not a scary proposition. If a rod were previously broken at the tip-top or ferrule, the section would be greater than 3/16" to 1/4" short. A break at the tip-top would result in a tip that is approximately 3/8" or more shorter than the other rod sections. A break at a ferrule would result in a section that is approximately one and a half inch or more shorter than the other sections.

An example of an undersized ferrule on a Dickerson rod

Rod production by the numbers

The most popular rod models in number of rods produced by Dickerson. In order from highest to lowest (number produced):

- 861711 (171)

- 901812 (148)

- 8013 (134)

- 8014 (114)

- 801510 (109)

- 761510 (73)

The six highest rod production years by Dickerson. In order from highest to lowest (production year):

- 177 (1946)

- 141 (1947)

- 123 (1948)

- 101 (1937)

- 85 (1949)

- 79 (1951)

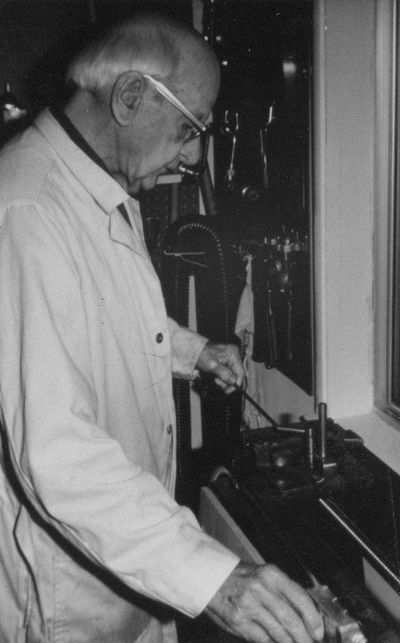

Lyle Dickerson in Tim Bedford's Calif. shop, circa 1973-74